-

HO-1 Chelating Resin: Advanced Solution for Heavy Metal Removal and Brine Refining

HO-1 chelating resin is a cutting-edge functional polymer material designed for selective adsorption and removal of heavy metal ions from industrial wastewater and brine solutions. As a highly specialized chelating resin, it features unique iminodiacetic acid functional groups that form stable coordinate complexes with heavy metal ions, enabling efficient heavy metal removal even in complex […]

-

HO-5 Amino phosphonic Chelating Ion Exchange Resin

Technical Specifications of HO-5 Ion Exchange Resin Parameter Specification Calcium Adsorption Capacity ≥2.4 mmol/ml Maximum Operating Temperature 90°C pH Range 1-12 Moisture Content 40-60% Wet True Density 1.10-1.20 g/ml Transformation expansion rate (H⁺→Na⁺) ≤40% Core Features of HO-5 Ion Exchange Resin The HO-5 resin boasts three defining characteristics that make it indispensable in critical industrial […]

-

Ion Exchange Resin Packaging Solutions For Global Trade

In the dynamic landscape of global trade, ion exchange resins serve as critical components across industries, from water treatment facilities to pharmaceutical manufacturing. With the global ion exchange resin market projected to reach $300 billion by 2030, the demand for reliable, compliant packaging solutions has never been greater. Our comprehensive packaging portfolio delivers precision-engineered solutions tailored […]

-

Ion Exchange Resin Storage and Transportation Guidelines

Resin storage and resin transportation are critical aspects of maintaining the performance and safety of ion exchange resins throughout their lifecycle. Improper handling during these stages can lead to resin degradation, reduced efficiency, and even safety hazards. Resin Storage: Environmental Controls and Best Practices Maintaining stable environmental conditions is paramount for resin storage. The ideal […]

-

Choose Macroporous Resin Or Gel Resin?

Macroporous resin and gel resin are two fundamental types of ion exchange resins with distinct structures and applications. Understanding their production processes, performance differences, and industrial uses is crucial for selecting the right resin for specific tasks, from water treatment to pharmaceutical purification. Production Processes of Macroporous Resin and Gel Resin Macroporous Resin Macroporous resin […]

-

Resin Polish: The Backbone of Ultra-Pure Water and High-Tech Manufacturing

Resin polish, a critical process in ion exchange technology, enables the production of ultra-pure water and high-performance materials for industries like nuclear energy and electronics. By leveraging ion exchange resins, this technique removes trace impurities, ensuring water and materials meet stringent purity standards. From powering nuclear reactors to enabling 5G semiconductors, resin polish plays a […]

-

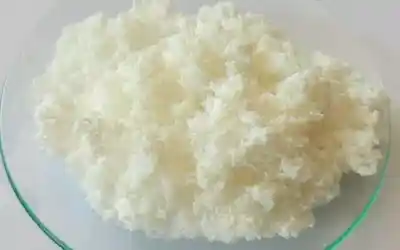

White Beads: The Precursor Skeleton of Ion Exchange Resins

White beads, the unfunctionalized polymer precursors of ion exchange resins, play a critical role in modern separation technology. These spherical particles, typically 1-2 mm in diameter, form the backbone structure that enables ion exchange processes in water treatment, pharmaceutical purification, and industrial separation applications. White Beads Production Process The manufacturing of white beads involves a […]

-

Ion Exchange Resin HG-3: Structure, Properties, and Applications

Ion exchange resins have become indispensable materials in modern separation and purification processes, with applications spanning water treatment, pharmaceuticals, and industrial manufacturing. Among these, the HG-3 ion exchange resin stands out as a specialized adsorbent engineered for high efficiency and versatility. Structural Characteristics of Ion Exchange Resin HG-3 Ion Exchange Resin HG-3 exhibits distinct structural […]

-

HF-20 Adsorption Resin: Technical Properties and Industrial Applications

1. Core Technical Specifications Parameter Index Appearance Light yellow spherical particles Moisture Content 55-65% Wet Bulk Density 0.65-0.75 g/ml Wet True Density 1.00-1.10 g/ml Particle Size (0.315-1.25mm) ≥90% Specific Surface Area ≥950 m²/g 2. Unique Structural Advantages The HF-20 resin exhibits three key technological breakthroughs: 3. Industrial Application Cases HF-20 has achieved remarkable results in […]

- Home

- About Us

- Products

- Juice Special use adsorbent resin

- Special adsorbent resin for wastewater treatment

- Special adsorbent resin for sugar industry

- Ion Exchange Resin

- Special resins for honey treatment

- Western medicine extraction and refining special adsorption resin

- Chinese medicine extraction and refining special adsorption resin

- Special resin for hydrogen peroxide purification

- Chelating resin

- catalytic resin

- Special resin integrated complete set of equipment

- Membrane filtration series products

- Case

- News

- Download

- Contact Us