Against the backdrop of increasingly stringent global environmental policies and growing demand for resource recycling, chelating resin—a functional polymer material capable of forming stable chelates with metal ions—has become a core technical support in industrial wastewater purification, precious metal recovery, and high-purity water preparation. According to QY Research’s 2025 industry report, the global market size for water treatment chelating resin has reached USD 896 million, projected to exceed USD 1.218 billion by 2031 with a CAGR of 4.5%. Among these, industrial wastewater treatment and hydrometallurgy account for over 60% of demand.

Unique Advantages of Chelating Resin: Beyond Traditional Ion Exchange Technology

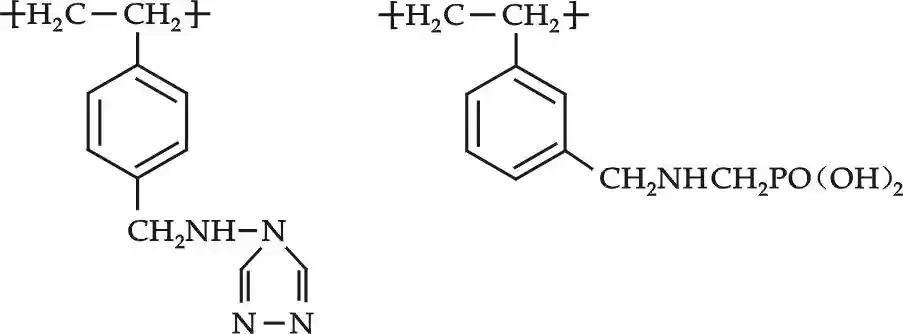

Unlike conventional ion exchange resins that rely on electrostatic adsorption, chelating resin forms coordinate bonds with metal ions through functional groups (e.g., iminodiacetic acid, aminophosphonic acid), offering stronger binding capacity and higher selectivity. For instance, iminodiacetic acid type chelating resin exhibits an adsorption capacity of over 50g/L for heavy metal ions such as copper, nickel, and cobalt under conditions of initial copper ion concentration 500mg/L, pH=5.0, and contact time 60 minutes. It maintains stable performance across a wide pH range (3-12), enabling precise capture of target ions in complex water matrices (e.g., high-salinity, high-organic-matter wastewater) and addressing ppm-level purification challenges that traditional precipitation methods cannot solve.

Figure 1: Schematic diagram of chelating resin functional groups and metal ion coordination (iminodiacetic acid and aminophosphonic acid types)

Core Application Scenarios: From Wastewater Purification to Resource Regeneration

1. Industrial Wastewater Advanced Treatment: Compliance Discharge and Pollutant Control

In electroplating, electronics, and chemical industries, chelating resin demonstrates efficient removal of heavy metal ions. For example, a semiconductor enterprise using aminophosphonic acid type chelating resin treated nickel-containing wastewater from 5mg/L to below 0.1mg/L, far exceeding the requirements of GB 21900-2008 (Electroplating Pollutant Discharge Standard). The resin regeneration cycle exceeds 1 month, reducing operating costs by 30%. Hairun’s chelating resin for industrial wastewater treatment, with acid corrosion resistance (pH 1-14) and high anti-pollution performance, has achieved stable operation in multiple PCB enterprises in the Yangtze River Delta region.

2. Precious Metal Recovery: Turning Waste into Green Economy

In hydrometallurgy, chelating resin‘s selective adsorption capacity for gold, silver, palladium, and other precious metals makes it a key technology for resource circulation. Data shows that using thiosuccinic acid type chelating resin to recover copper from electroplating wastewater achieves 99.5% adsorption efficiency and 99.9% purity, recovering approximately RMB 2,000 worth of metal resources per ton of wastewater.

Figure 2: On-site application of chelating resin in industrial wastewater treatment systems (blue tanks are resin adsorption towers)

3. Ion-Exchange Membrane Caustic Soda Refining: Ensuring Critical Process Stability

In ion-exchange membrane caustic soda production, impurities like Ca²⁺, Mg²⁺, and Sr²⁺ in brine cause membrane poisoning and reduce electrolysis efficiency.Aminophosphonic acid type chelating resin reduces calcium and magnesium ion concentrations in secondary brine to below 0.02ppm, extending membrane lifespan to over 3 years and reducing energy consumption by 15% compared to traditional processes. This technology has been certified by the China Chlor-Alkali Industry Association and is widely used in large-scale chlor-alkali enterprises in Shandong and Jiangsu provinces.

Industry Trends: Policy and Technology Driving Growth

As China’s 14th Five-Year Plan lists chelating resin as a key strategic material and the EU REACH regulation tightens heavy metal limits, the industry faces three major opportunities:

- High Performance: High-temperature resistant and radiation-resistant resins have begun application exploration in complex scenarios such as high-salinity and high-radioactivity wastewater;

- Intelligence: IoT-integrated online resin performance monitoring systems enable dynamic optimization of regeneration cycles;

- Greenification: R&D breakthroughs in bio-based chelating resin have achieved over 90% biodegradation rate.

Hairun’s integrated “resin + equipment + service” model provides customers with full-lifecycle solutions from process design to operation.

Conclusion: Choose Chelating Resin to Build a Green Production Future

Whether for industrial wastewater discharge compliance, precious metal resource recycling, or water quality assurance in high-end manufacturing, chelating resin plays an irreplaceable role. Hairun, driven by technological innovation, is committed to providing more efficient, economical, and sustainable separation and purification solutions.

Contact Hairun’s technical team now to obtain customized chelating resin application solutions and jointly promote industrial green transformation and resource sustainable development.

Learn More: