1. Core Technical Specifications

| Parameter | Index |

| Appearance | Light yellow spherical particles |

| Moisture Content | 55-65% |

| Wet Bulk Density | 0.65-0.75 g/ml |

| Wet True Density | 1.00-1.10 g/ml |

| Particle Size (0.315-1.25mm) | ≥90% |

| Specific Surface Area | ≥950 m²/g |

2. Unique Structural Advantages

The HA-185 resin exhibits three key technological breakthroughs:

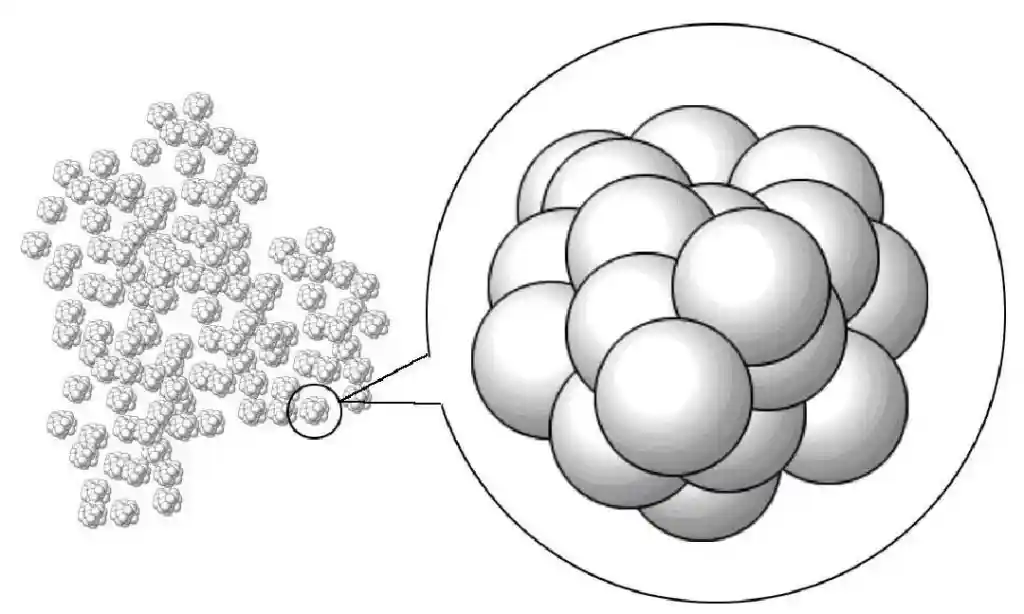

- Ultra-high Specific Surface Area: With ≥950 m²/g, it provides 2-3 times higher adsorption capacity than conventional gel-type resins (<500 m²/g), enabling efficient removal of trace organic contaminants.

- Precision Pore Architecture: Controlled pore size distribution allows selective adsorption of medium molecular weight organics, ideal for separating pigments and natural products.

- Chemical Stability: Styrene-divinylbenzene matrix demonstrates excellent resistance to acids and organic solvents.

3. Industrial Application Cases

HA-185 has achieved remarkable results in multiple sectors:

- Pharmaceutical Industry: A leading API manufacturer implemented HA-185 for phenol recovery, converting waste treatment into annual profits exceeding ¥1 million.

- Chemical Wastewater Treatment: In Xingfa Group’s Yichang plant, HA-185 system reduced COD levels in acidic wastewater, meeting strict discharge standards while recovering valuable organic acids.

- Food Processing: Applied in citrus polyphenol purification, supporting functional food development with natural antioxidants.

4. Market Context and Technical Trends

The global resin market is projected to reach USD 623.27 billion by 2025, with environmental applications growing at 5.0% CAGR. HA-185 represents the next-generation adsorption technology by addressing three critical industry challenges:

1.Resource Recovery Economics: Single-solvent recovery (e.g., ethyl acetate) , creating new revenue streams from waste streams.

2.Halogenated Compound Treatment: Effectively removes difficult-to-treat VOCs like dichloroethane, eliminating RTO corrosion risks in pharmaceutical manufacturing.

3.Process Intensification: Enables integration with deep cooling/incineration systems, handling high-concentration waste streams that traditional technologies cannot manage.

As industries shift from “end-of-pipe treatment” to “resource circularity,” HA-185’s combination of high selectivity, regeneration efficiency, and mechanical stability positions it as a cornerstone technology for sustainable manufacturing.