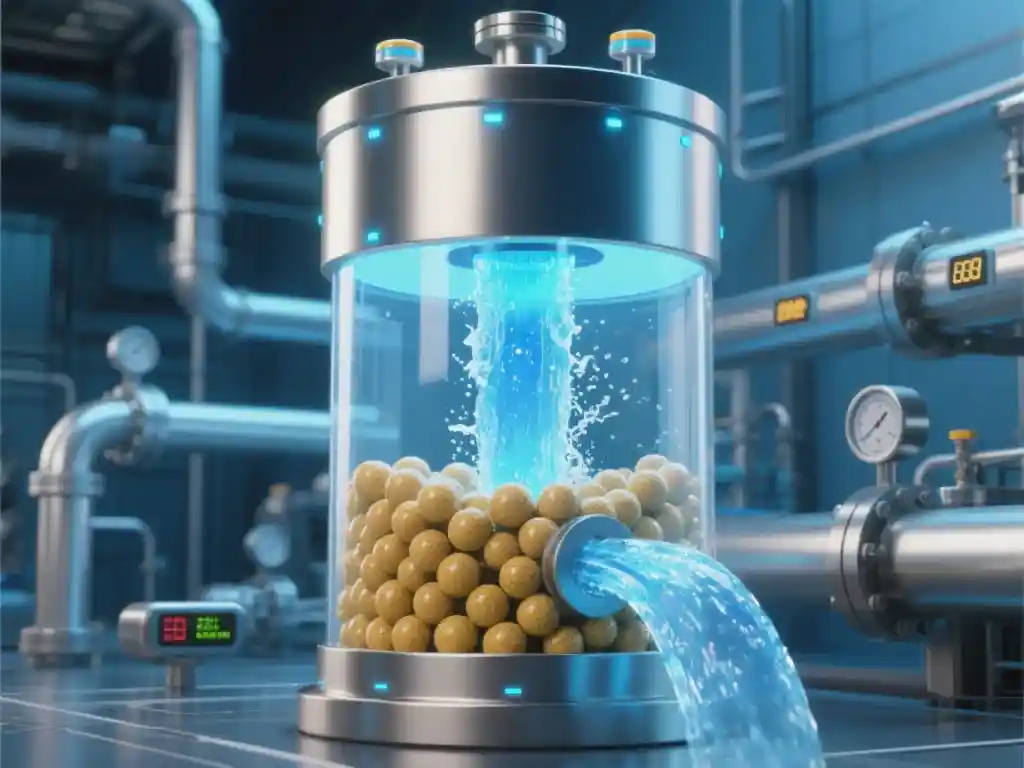

Ion Exchange Resin is a polymeric material with ion exchange functionality, consisting of an insoluble three-dimensional network skeleton and active groups attached to the skeleton. These active groups can dissociate ions in water, thereby exchanging with other like ions in the solution. As an efficient separation and purification technology, ion exchange resin has become an indispensable key material in water treatment, pharmaceuticals, chemicals, and other fields.

Working Principle and Structural Characteristics of Ion Exchange Resin

The core working mechanism of ion exchange resin is based on reversible ion exchange reactions. When the resin comes into contact with a solution containing target ions, the active groups on the skeleton release exchangeable ions (such as H⁺ or OH⁻) while adsorbing the ions to be removed from the solution. This exchange process follows the “equivalent charge exchange” principle—for example, 1 mole of Ca²⁺ will displace 2 moles of Na⁺.

The three-dimensional network structure of the resin determines its physical stability, while the type of active groups determines its exchange performance. Modern ion exchange resins typically have a pore size of 10-50nm and an exchange capacity of 1-10mmol/g, capable of stable operation over a wide temperature range (0-120°C) and pH range (1-14).

Classification and Technical Parameters of Ion Exchange Resin

Based on the nature of active groups, ion exchange resins are mainly classified into two categories:

Application Scenarios of Cation Exchange Resins

These resins contain acidic groups (such as sulfonic acid groups -SO₃H or carboxyl groups -COOH) and can exchange with cations in solution (such as Ca²⁺, Mg²⁺, Pb²⁺). In water softening, sulfonic acid-type resins can replace calcium and magnesium ions in water with sodium ions, reducing water hardness from 300mg/L to below 50mg/L.

Performance Advantages of Anion Exchange Resins

Anion exchange resins contain basic groups (such as quaternary ammonium groups -N(CH₃)₃⁺) and are mainly used to remove anionic contaminants from water (such as Cl⁻, SO₄²⁻, NO₃⁻). In ultrapure water preparation for the electronics industry, strong base anion resins can reduce TOC (Total Organic Carbon) in water to below 5ppb, meeting the stringent requirements of chip manufacturing.

2025 Industry Application Cases and Data

Breakthrough Applications in Water Treatment

In municipal wastewater treatment, ion exchange resins have achieved deep removal of heavy metal ions. After a municipal wastewater treatment plant adopted a chelating resin process, the concentration of lead and cadmium in wastewater was reduced from 0.5mg/L to below 0.001mg/L, meeting the highest standards of the EU Water Framework Directive.

Purification Revolution in Pharmaceutical Industry

In antibiotic production, ion exchange resins have replaced traditional solvent extraction methods, increasing the purity of cephalosporin drugs to 99.9% while reducing organic solvent usage by 80%. According to a 2024 report by Pharmaceutical Technology, resin purification technology can reduce drug production costs by 35%.

Future Development Trends and Environmental Value

The regenerative capacity of ion exchange resins makes them a model for the circular economy. Through acid-base regeneration, resins can be reused 500-1000 times, with a lifecycle cost only 1/5 that of disposable adsorption materials. In 2025, bio-based ion exchange resins will achieve commercial application, with a carbon footprint 40% lower than traditional resins.