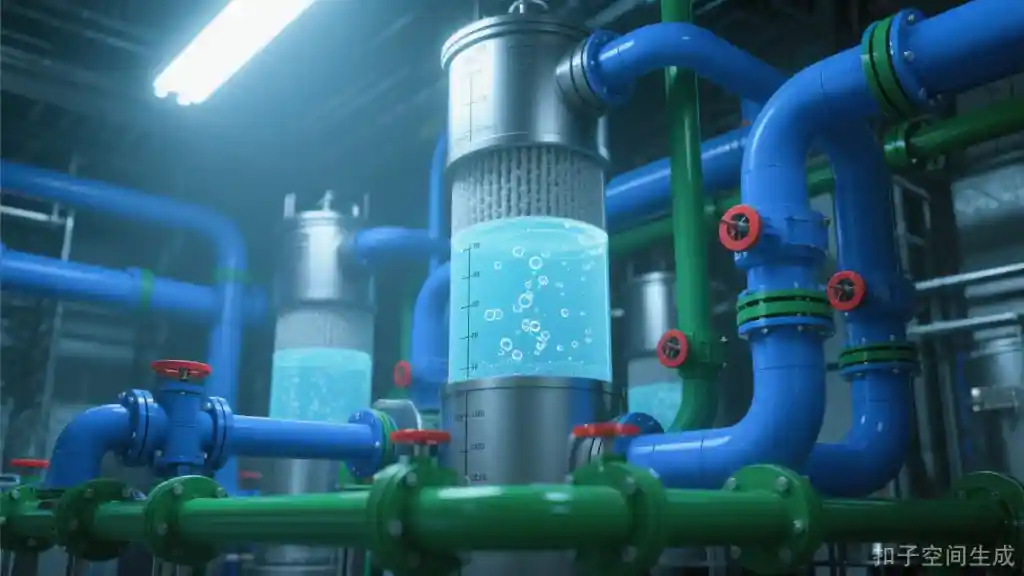

Ion exchange resin technology has revolutionized water treatment and purification processes across industries, and 001×8 stands out as a versatile and high-performance variant. This gel-type strong acid cation exchange resin, characterized by its sulfonated polystyrene-divinylbenzene (DVB) matrix, offers exceptional ion exchange capacity, chemical stability, and adaptability to extreme conditions. In this article, we explore the unique properties of 001×8, its wide-ranging applications in industrial waste water treatment and industrial water purification, and why it remains a preferred choice for critical purification processes.

Key Properties of Ion Exchange Resin 001×8

001×8 is engineered to deliver superior performance in demanding environments. Its core attributes include:

1. High Exchange Capacity

With a total exchange capacity of ≥2.0 mmol/ml (volumetric), 001×8 efficiently removes cations such as calcium (Ca²⁺), magnesium (Mg²⁺), and heavy metals from water streams. This high capacity reduces regeneration frequency, lowering operational costs.

2. Broad pH and Temperature Tolerance

The resin operates effectively across the entire pH spectrum (0–14) and withstands temperatures up to 120°C in sodium (Na⁺) form and 100°C in hydrogen (H⁺) form. This stability makes it suitable for both acidic and alkaline industrial effluents.

3. Mechanical Strength and Uniformity

Its 8% cross-linked structure (higher than the 7% of 001×7) enhances mechanical durability, minimizing bead breakage during backwashing and regeneration. The particle size range (0.315–1.25 mm, ≥95%) and uniformity coefficient (≤1.6) ensure consistent flow dynamics and reduced pressure drop in columns.

4. International Equivalence

001×8 is comparable to leading global brands, including Dowex HCR-S, Amberlite IR-120, and Purolite C100, ensuring compatibility with existing systems and global supply chains.

Industrial Applications of Ion Exchange Resin 001×8

1. Industrial Water Purification

001×8 is a cornerstone of pure and high-purity water production. For example, when paired with anion exchange resins, it produces ultra-pure water for semiconductor manufacturing, where even trace impurities can compromise product quality.

2. Industrial Waste Water Treatment

The resin excels in removing heavy metals and hardness from industrial effluents. This not only met environmental discharge norms but also mitigated water scarcity risks.

3. Food and Pharmaceutical Industries

In food processing, 001×8 is used for sugar decolorization and beverage clarification. In pharmaceuticals, it aids antibiotic extraction and drug purification, leveraging its ability to selectively bind target molecules.

Technical Specifications and Operational Guidelines

Typical Physical and Chemical Properties

| 001*8 Uniform grain cationic resin | ||

| GENERAL DESCRIPTION | ||

| Matrix | Styrene-DVB | |

| Functional group | Sulfonic acid | |

| Polymer structure | Gel | |

| lonic form | H⁺Hydrogen | Na+Sodium |

| Physical and Chemical Characteristics: | ||

| CHARACTERISTICS | STANDARD VALUE | |

| lonic form | H+ | Na |

| Mean particle size,mm | 0.65±0.05 | |

| Uniformity coefficient,max | 1.1 | |

| Moisture retention,in CI form% | 48-55 | |

| Osmotic stability,%,min | 98 | |

| Total capacity,mmol/cm³(mg-eq/cm³),min | 1.9 | 2.0 |

| Shipping weight,g/cm³ | 0.75-0.80 | 0.80-0.85 |

Conclusion

Ion exchange resin 001×8 combines robust performance, versatility, and compliance, making it indispensable for industrial water purification and industrial waste water treatment. This ion exchange resin’s high exchange capacity, broad operational window, and compatibility with global standards position it as a reliable solution for industries striving for efficiency and sustainability.

For more technical details, please contact us for customized application support.