Ion exchange resins have become indispensable materials in modern separation and purification processes, with applications spanning water treatment, pharmaceuticals, and industrial manufacturing. Among these, the HG-3 ion exchange resin stands out as a specialized adsorbent engineered for high efficiency and versatility.

Structural Characteristics of Ion Exchange Resin HG-3

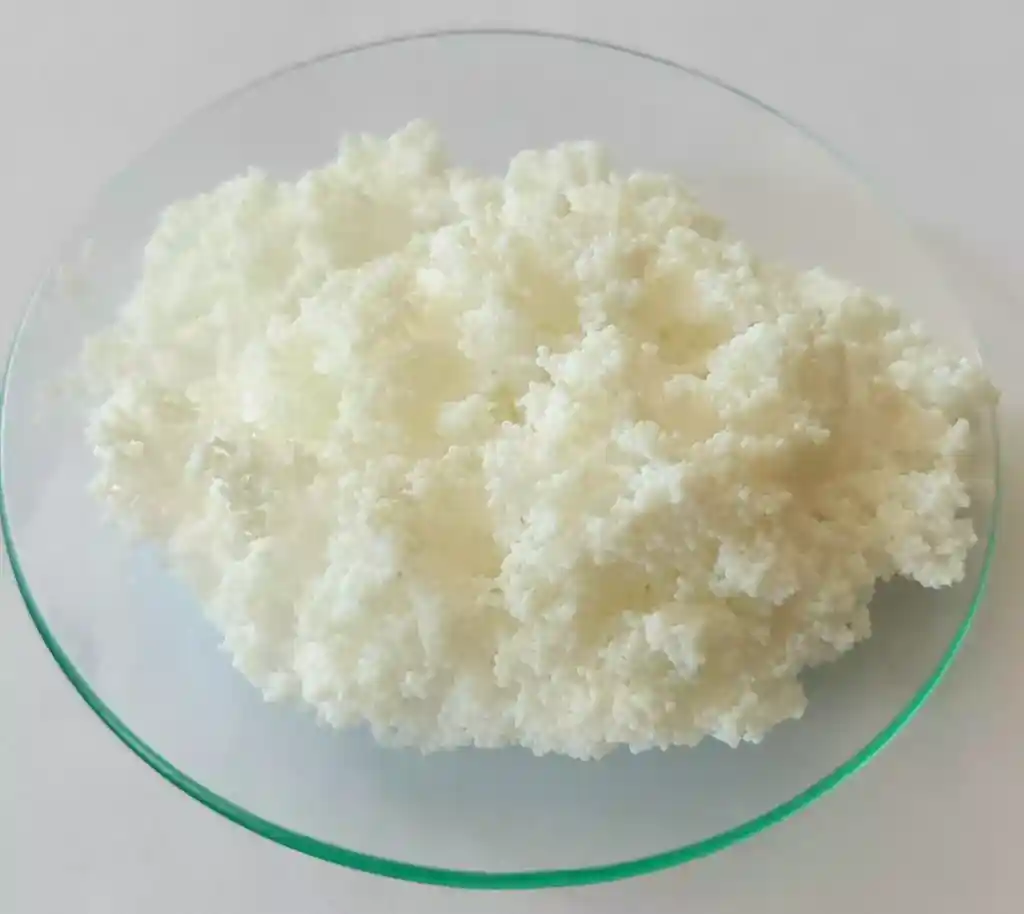

Ion Exchange Resin HG-3 exhibits distinct structural features that underpin its ion exchange performance and practical applicability. Its structure is fundamentally composed of two core components: a polymeric framework (skeleton) and functional groups, following the general architecture of ion exchange resins. The active sites, known as epoxy functional groups, are covalently attached to this skeleton and serve as the critical components responsible for ion exchange capacity.

Key Physical and Chemical Structural Parameters

- Mechanical robustness: Resists fragmentation under pressure/backwashing; >95% particle uniformity reduces fluid resistance.

- Catalytic efficiency: High enzyme loading capacity via microporous structure; consistent batch performance.

- Operational adaptability: pH tolerance (6.5–9.5), optimal physical properties (63.2% water content, 0.76 g/ml wet density), and environmental functionality (Hg²⁺ removal).

Application Fields

Water Treatment

HG-3 is widely used in drinking water purification to remove hardness ions (Ca²⁺, Mg²⁺) and heavy metals, achieving residual concentrations below WHO guidelines. In industrial wastewater treatment, it efficiently recovers precious metals (Au³⁺, Ag⁺) from electroplating effluents, with recovery rates exceeding 99.5%.

Pharmaceutical and Biotechnology

In pharmaceutical manufacturing, HG-3 serves as a critical adsorbent for API purification, separating chiral isomers and removing ionic impurities from drug solutions.

Food and Beverage Industry

The resin is employed in sugar refining to decolorize molasses and remove ash-forming ions, improving product clarity and shelf life. In brewing, it stabilizes beer by reducing sulfate and chloride levels, enhancing flavor consistency.

Conclusion

The HG-3 ion exchange resin represents a significant advancement in adsorbent technology, combining high capacity, stability, and selectivity to address diverse industrial challenges. Its robust structural design and performance metrics make it a preferred choice in water treatment, pharmaceuticals, and food processing.

As industries increasingly prioritize sustainability and efficiency, HG-3 is poised to play a pivotal role in enabling greener processes, from resource recovery to pollution control. Future innovations may further optimize its functional groups and porosity, expanding its applications into emerging fields such as energy storage and environmental remediation.