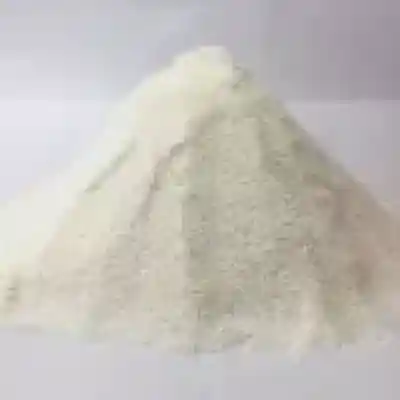

Resin storage and resin transportation are critical aspects of maintaining the performance and safety of ion exchange resins throughout their lifecycle. Improper handling during these stages can lead to resin degradation, reduced efficiency, and even safety hazards.

Resin Storage: Environmental Controls and Best Practices

Maintaining stable environmental conditions is paramount for resin storage. The ideal temperature range is 5–40°C, as temperatures exceeding 40°C can cause anion resin degradation, particularly for OH-form resins, while freezing temperatures below 0°C may lead to bead breakage due to ice expansion. Relative humidity should be controlled between 50–70% to prevent moisture absorption or loss, which can cause resin swelling or shrinkage.

Stacking height is another critical factor—resin packages should not exceed 1.5 meters to avoid compression damage to lower layers. For long-term storage, especially in cold climates, using a concentrated NaCl solution (10–25%) prevents freezing and microbial growth.

Resin Transportation: Regulatory Compliance and Packaging Standards

Resin transportation is governed by international regulations, with most ion exchange resins classified as UN 1866 (Class 3 Flammable Liquid) under the IMDG Code forsea transportation. IATA guidelines forair freight require triple-layer packaging: leakproof primary containers, absorbent secondary packaging, and rigid outer packaging marked with hazard labels and UN numbers.

By adhering to these guidelines, facilities can ensure resin integrity during resin storage and resin transportation, maintaining regulatory compliance and operational safety for resin transportation.

Disclaimer: Hairun Resin and its affiliates expressly disclaim all express or implied warranties (including, without limitation, warranties of timeliness, accuracy, completeness, reliability, or fitness for a particular purpose) with respect to the content of this document (including forward-looking statements). Neither Hairun Resin nor its affiliates shall be held liable for any consequences arising from errors, omissions, or other deficiencies in the document.