Chelating resin HA-30 plays a pivotal role in modern industrial processes, particularly in the treatment of acidic waste liquid and Recycling rhenium—a rare and valuable metal critical to aerospace and energy sectors.

Unique Properties of Chelating Resin HA-30 for Recycling Rhenium

Resin HA-30 is engineered as a macroporous weak-base anion exchange resin with mixed amino functional groups, designed to selectively bind perrhenate ions (ReO₄⁻) in highly acidic environments. Its key characteristics include:

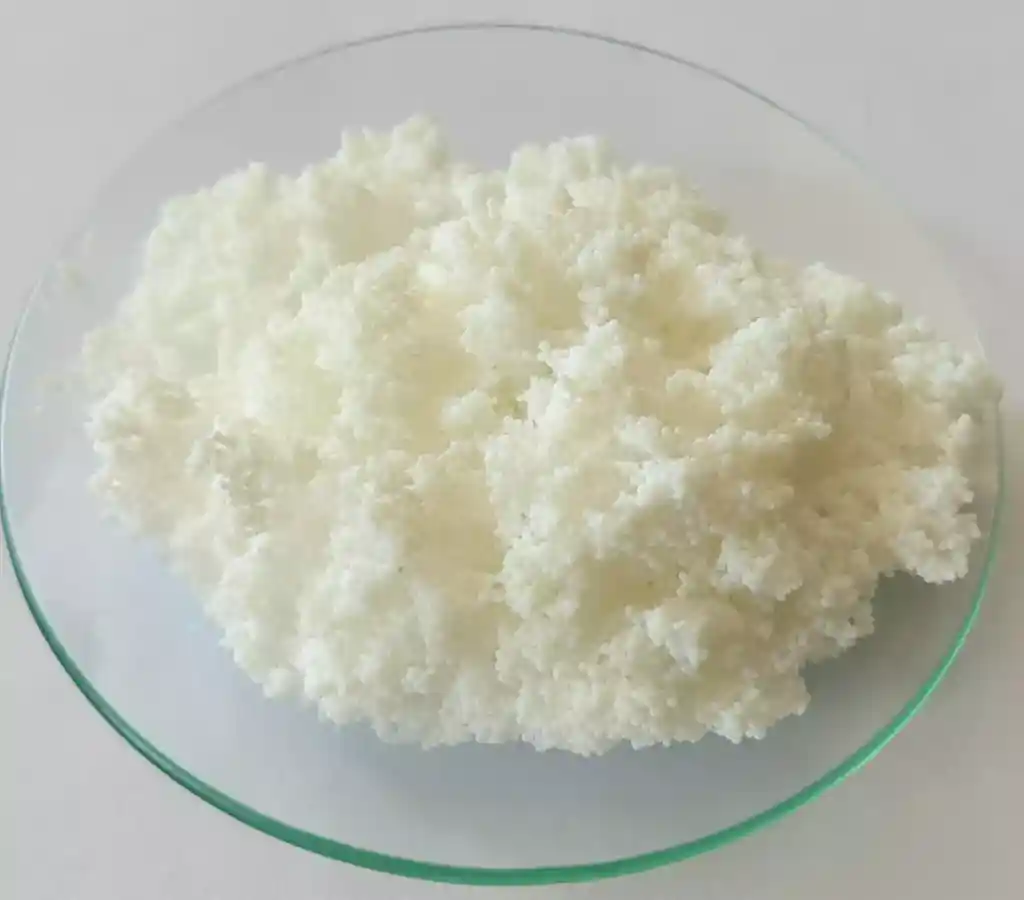

| Property | Technical Specification |

| Appearance | Light yellow opaque spherical beads |

| Particle Size (0.315-1.25mm) | ≥95.0% |

| Total Exchange Capacity | ≥3.0 mmol/g |

| Wet Bulk Density | 0.67–0.72 g/mL |

| Crush Strength | ≥90% |

| Water Content | 40% |

Resin HA-30 porous structure (3–15 nm pore size) and highly selective amino groups enable efficient separation of rhenium from molybdenum, copper, and iron ions, Unlike conventional ion exchangers, it exhibits rapid adsorption kinetics and excellent desorption efficiency.

Applications in Acidic Waste Liquid Treatment

1. Rhenium Recovery from Mining Waste Streams

In molybdenum and copper smelting, rhenium occurs as a trace impurity (0.001–0.01% by weight) in sulfide ores. During roasting, it volatilizes as Re₂O₇ and dissolves in acidic scrubber solutions, forming dilute perrhenate (ReO₄⁻) streams. Chelating resin HA-30 treat these streams to recover rhenium, achieving 98%+ adsorption efficiency even at pH < 2.

2. Environmental Compliance & Waste Minimization

Stringent regulations, such as the U.S. EPA’s Resource Conservation and Recovery Act (RCRA), mandate the treatment of hazardous acidic wastes to prevent heavy metal contamination. Rhenium extraction resin HA-30 systems reduce rhenium concentrations in effluents to <0.1 mg/L, meeting discharge standards while converting waste into a valuable resource.

Technical Advantages Over Conventional Methods

Compared to solvent extraction or precipitation, rhenium selective resin offers:

- Higher selectivity: Preferentially binds ReO₄⁻ over SO₄²⁻ and Cl⁻ ions.

- Lower operational costs: Eliminates organic solvent usage and reduces energy consumption by 30%.

- Scalability: Modular design allows treatment capacities from 10 to 10,000 m³/day.

Future Trends: Toward Sustainable Rhenium Supply

With the global rhenium market projected to grow at 14.5% CAGR (2025–2032), driven by aerospace superalloy demand, resin-based recycling technologies will play a critical role in reducing reliance on primary mining. Innovations in functionalized resins, such as nanoparticle-enhanced adsorption, aim to boost capacity to >400 mg/g by 2030.

Chelating resin HA-30 combines high selectivity, environmental sustainability, and economic viability—making it indispensable for treatment of acidic waste liquid and Recycling rhenium in the circular economy.

Disclaimer: Hairun Resin and its affiliates expressly disclaim all express or implied warranties (including, without limitation, warranties of timeliness, accuracy, completeness, reliability, or fitness for a particular purpose) with respect to the content of this document (including forward-looking statements). Neither Hairun Resin nor its affiliates shall be held liable for any consequences arising from errors, omissions, or other deficiencies in the document.