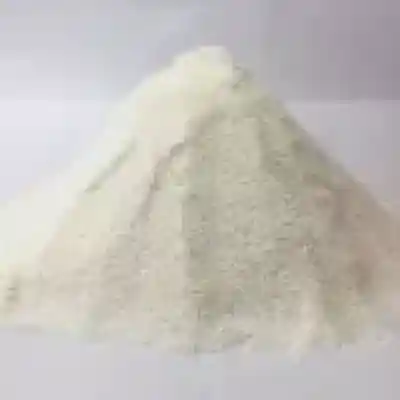

White beads, the unfunctionalized polymer precursors of ion exchange resins, play a critical role in modern separation technology. These spherical particles, typically 1-2 mm in diameter, form the backbone structure that enables ion exchange processes in water treatment, pharmaceutical purification, and industrial separation applications.

White Beads Production Process

The manufacturing of white beads involves a sophisticated suspension polymerization process that transforms two immiscible phases into crosslinked polymer spheres.

Key Production Stages:

1. Raw Material Mixing: Styrene and DVB are mixed in precise ratios to control crosslinking density. This mixture forms the oil phase which is dispersed into the aqueous phase under high shear mixing to create micron-sized droplets.

2. Suspension Polymerization: The reaction vessel is gradually heated from 80°C to 155°C, triggering polymerization. The temperature profile is carefully controlled to prevent bead agglomeration and ensure uniform crosslinking.

3. Curing and Post-Treatment: After polymerization, the beads undergo curing to relieve internal stresses, followed by washing to remove residual monomers and initiators. Sieving ensures uniform particle size distribution, a critical parameter for resin performance.

The choice between gel-type and macroporous white beads depends on application requirements. Gel-type beads, formed without porogens, offer high mechanical strength for standard water softening, while macroporous variants—produced by adding volatile porogens—exhibit enhanced mass transfer properties for complex separations.

Mechanism of Action

White beads function as inert frameworks that gain ion exchange capabilities through subsequent functionalization. Their polymeric structure, typically polystyrene-divinylbenzene copolymers, provides three-dimensional networks with controlled porosity and crosslinking density.The high polymer variant offer superior durability in harsh operating conditions.This structure is essential for applications like protein purification and catalyst support.

Industrial Applications

White beads serve as the foundation for numerous specialized resins, enabling critical processes across industries:

Water Treatment

In municipal and industrial water purification, white bead-derived resins remove contaminants through ion exchange.

Food and Pharmaceutical Industries

The food sector relies on white bead-based resins for sugar decolorization and beverage purification.

Advanced Materials

Carbonized white beads function as high-performance catalyst supports.

Conclusion

As essential components in separation science, white beads will continue to enable technological advancements in water treatment, pharmaceuticals, and materials science. Their adaptability and performance make them indispensable in the pursuit of cleaner processes and more efficient industrial operations.

Disclaimer: Hairun Resin and its affiliates expressly disclaim all express or implied warranties (including, without limitation, warranties of timeliness, accuracy, completeness, reliability, or fitness for a particular purpose) with respect to the content of this document (including forward-looking statements). Neither Hairun Resin nor its affiliates shall be held liable for any consequences arising from errors, omissions, or other deficiencies in the document.